Chain Slings

Chain Slings

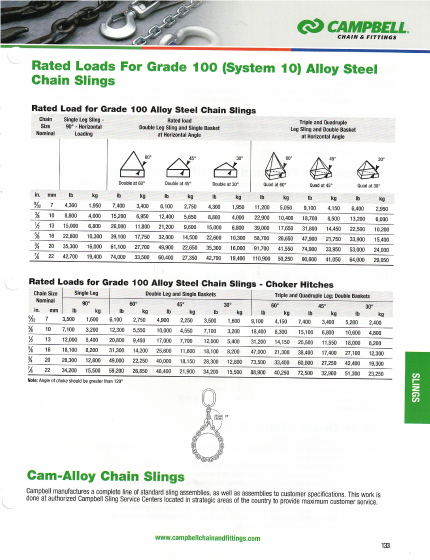

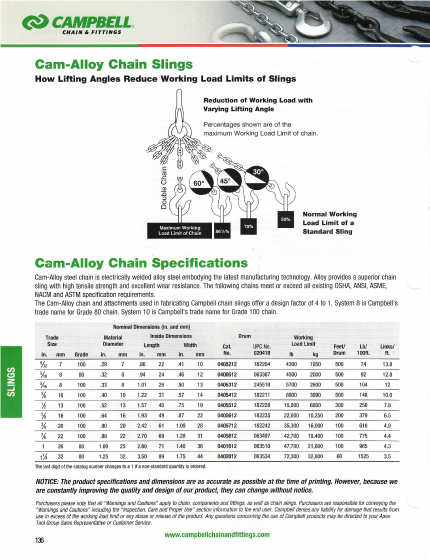

System 10 Cam-Alloy Chain Slings

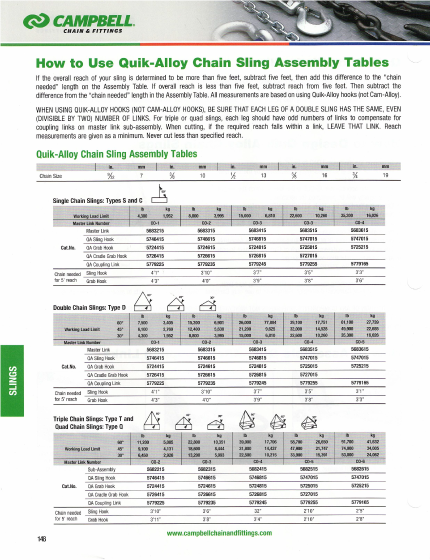

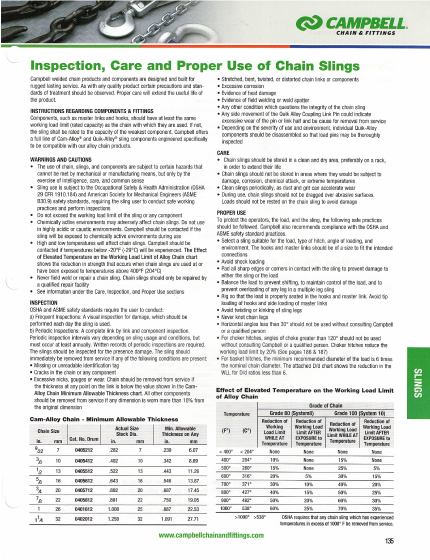

Chain Sling Capacities (In Lbs.)

| Size in | Single Leg | Two Leg Slings | Three & Four Leg Stlings | ||||

| Vertical | 60 Degree | 45 Degree | 30 Degree | 60 Degree | 45 Degree | 30 Degree | |

| 9/32 | 4,300 | 7,400 | 6,100 | 4,300 | 11,200 | 9,100 | 6,450 |

| 3/8 | 8,800 | 15,200 | 12,400 | 8,800 | 22,800 | 18,600 | 13,200 |

| 1/2 | 15,000 | 26,000 | 21,200 | 15,000 | 39,000 | 31,800 | 22,500 |

| 5/8 | 22,600 | 39,100 | 32,000 | 22,600 | 58,700 | 47,900 | 33,900 |

| 3/4 | 35,300 | 61,100 | 49,900 | 35,300 | 91,700 | 74,900 | 53,000 |

| 7/8 | 42,700 | 74,000 | 60,400 | 42,700 | 110,900 | 90,600 | 64,000 |

The Rigging Box, Inc. manufactures a complete line of standard chain sling assemblies, as well as assemblies to customer specifications, using Campbell® System 10 Grade 100 components.

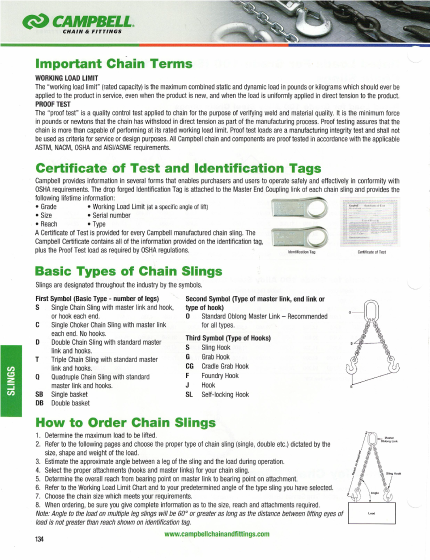

Important Chain Terms

WORKING LOAD LIMIT

The “working load limit” (rated capacity) is the maximum combined static and dynamic load in pounds or kilograms which should ever be applied to the product in service, even when the product is new, and when the load is uniformly applied in direct tension to the product.

PROOF TEST

The “proof test” is a quality control test applied to chain for the purpose of verifying weld and material quality. It is the minimum force in pounds or newtons that the chain has withstood in direct tension as part of the manufacturing process. Proof testing assures that the chain is more than capable of performing at its rated working load limit. Proof test loads are a manufacturing integrity test and shall not be used as criteria for service or design purposes. All Campbell chain and components are proof tested in accordance with the applicable ASTM, NACM, OSHA and AISI/ASME requirements.

Certificate of Test and Identification Tags

Campbell provides information in several forms that enables purchasers and users to operate safely and effectively in conformity with OSHA requirements. The drop forged Identification Tag is attached to the Master End Coupling link of each chain sling and provides the following lifetime information:

Grade

Working Load Limit (at a specific angle of lift)

Size

Serial number

Reach

Type

A Certificate of Test is provided for every Campbell manufactured chain sling. The Rigging Box, Inc. Certificate contains all of the information provided on the identification tag, plus the Proof Test load as required by OSHA regulations.

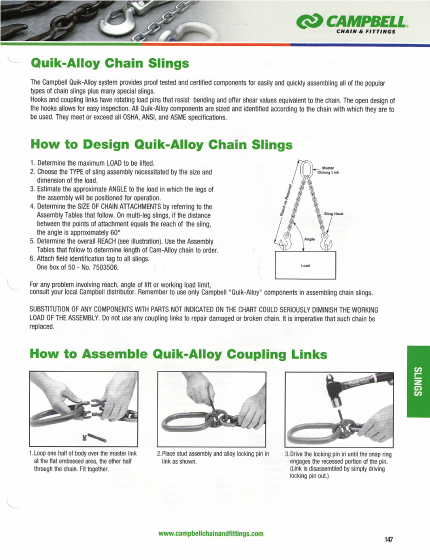

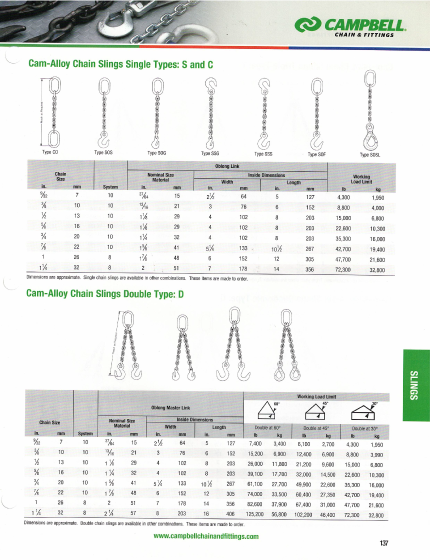

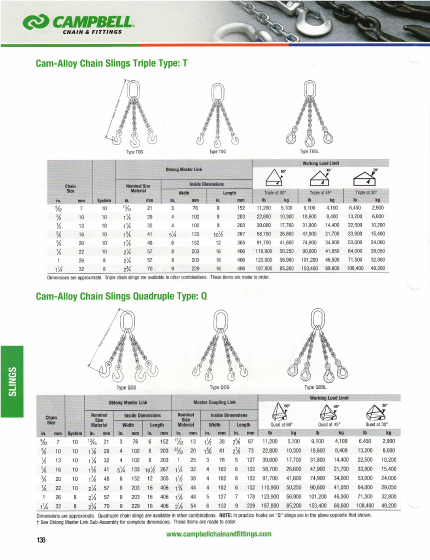

Basic Types of Chain Slings

Slings are designated throughout the industry by these symbols.

First Symbol (Basic type)

S-Single Chain Sling with master link and hook, or hook each end.

C-Single Choker Chain Sling with master link each end. No hooks.

D-Double Chain Sling with standard master link and hooks.

T-Triple Chain Sling with standard master link and hooks.

Q-Quadruple Chain Sling with standard master link and hooks.

SB-Single basket

DB-Double basket

Second Symbol (Type of master link or end link)

O-Standard Oblong Master Link–Recommended for all types.

A-Adjustable (A 1′ chain leg with grab hook)

Third Symbol (Type of Hooks)

S-Sling Hook

G-Grab Hook

F-Foundry Hook

CAM-Self-locking Hook

How to Order Chain Slings?

1. Determine the maximum load to be lifted.

2. Refer to the following pages and choose the proper type of chain sling (single, double, etc.) dictated by the size, shape and weight of the load.

3. Estimate the approximate angle between a leg of the sling and the load during operation.

4. Select the proper attachments (hooks and master links) for your chain sling.

5. Determine the overall reach from bearing point on master link to bearing point on attachment.

6. Refer to the Working Load Limit Chart and to your predetermined angle of the type sling you have selected.

7. Choose the chain size which meets your requirements.

8. When entering your order be sure you give complete information as to the size, reach and attachments required.

Note: Angle to the load on multiple leg slings will be 60° or greater as long as the distance between lifting eyes of load is not greater than reach shown on identification tag.